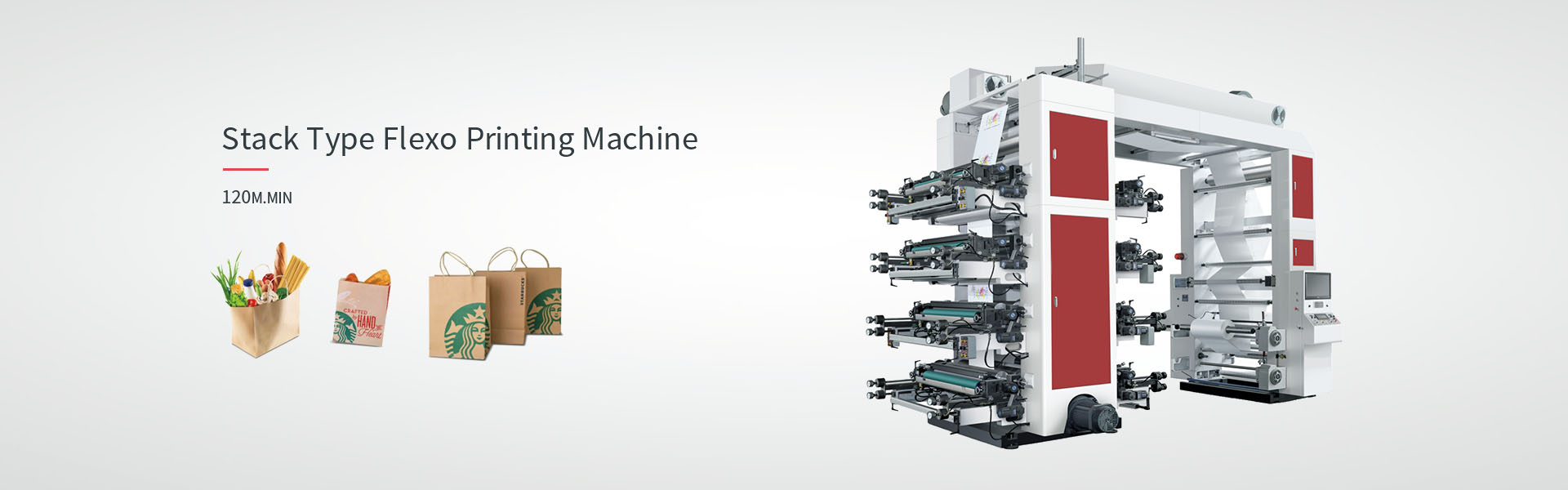

HMI introduced “LENZE,GERMANY”, easy for operation

Motion controller introduced “LENZE,GERMANY”, optical fiber integration

Servo motor introduced “Rexroth,Germany”, with stable running state

Photo electricity sensor introduced “Sick,Germany”, precisely tracking printing bag

Hydraulic material reel loading/unloading

Automatic tension control

Web alinger introduced “SELECTRA,ITALY”, to reduce adjustment time

-Provide Solutions

Set out plans as per samples or technical drawing

-Product Development

Specification can be modified as plan develops

-Customer Confirmation

Start of fabrication once O/D confirmed

-Machine Test

As per client’s designated paper weight until test acceptance

-Packaging

Damp proof and exported wooden box

- Delivery

By air or ocean

Q: Could you send me an offer with print section for 2 or 4 colors

A: Yes, it shall be inline flexo printer

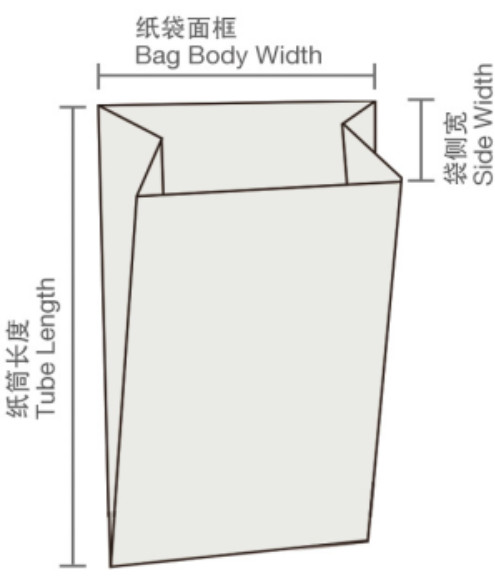

Q: Are this machine equipped with window and V-size bottom, without handle?

A: Yes, but it’s better to show us bag sample, just in case error

Q: Do you know which kind of plastic film should we use for window ?

A: Most users would adopt OPP/PET that between 0.012-0.0037mm

Q: Is it possible for machine to reach capacity like 500pcs/min?

A: Yes, it can up to 650pcs/min at the maximum

Q: What is the delivery time?

A: 2 months