-Provide Solutions

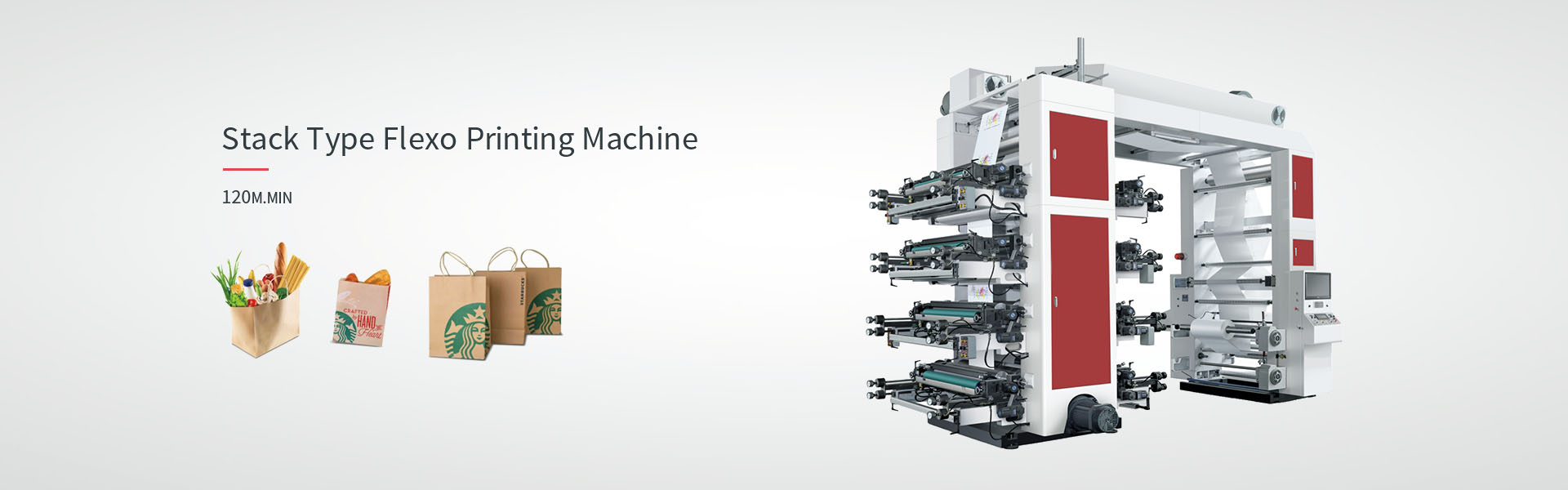

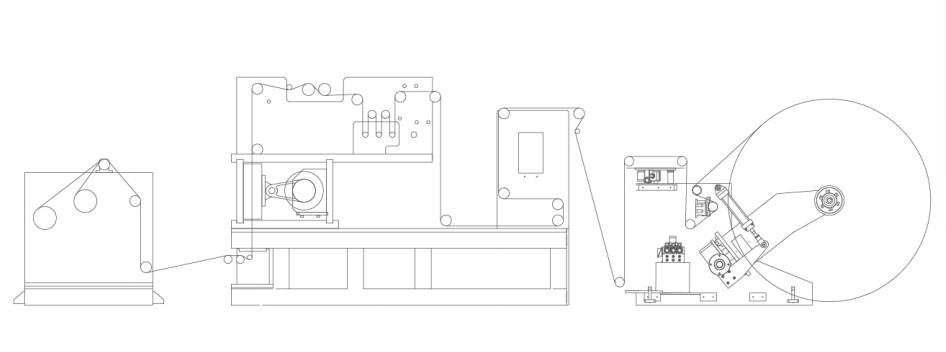

According to user’s sample to provide machine type

-Product Development

Configuration can be modified by different brands

-Customer Confirmation

Start of fabrication once O/D confirmed

-Machine Test

Test per user’s product drawing and paper thickness

-Machine Delivery

By sea or train

-Packaging Way

Moisture - proof packaging

Q: How long does it take to change tools/molds for punching ?

A: 40-60min required when we turn to another new punching job

Q: Any difference between Switzerland and Japanese Molds ?

A: Switzerland brand: 7000,0000 punching times/blade grinding; Japanese brand: 2000,0000 punching times/blade grinding

Q: Machine has CE approval and meets all European standards ?

A: Yes, CE certificate is included

Q: Any optional accessories suggested ?

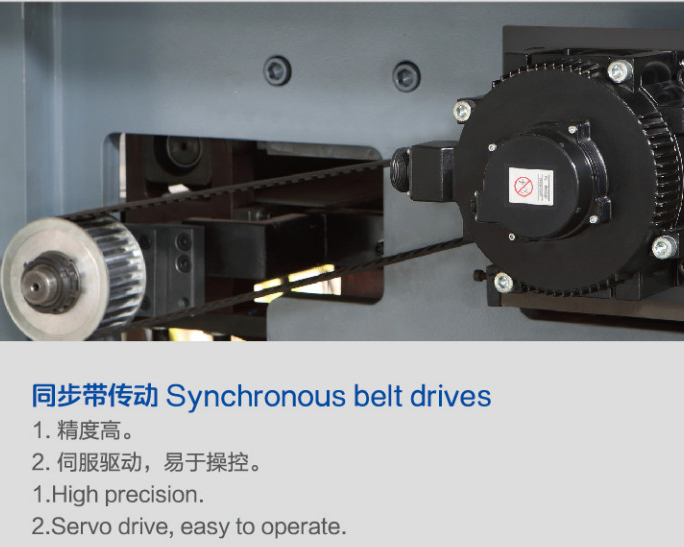

A: Most users would adopt mold car and plate mounting machine , to ensure easy molds replacement and lessen error when paste the print plate on the printing cylinder

Q: How about production time after money transferred?

A: 50 days