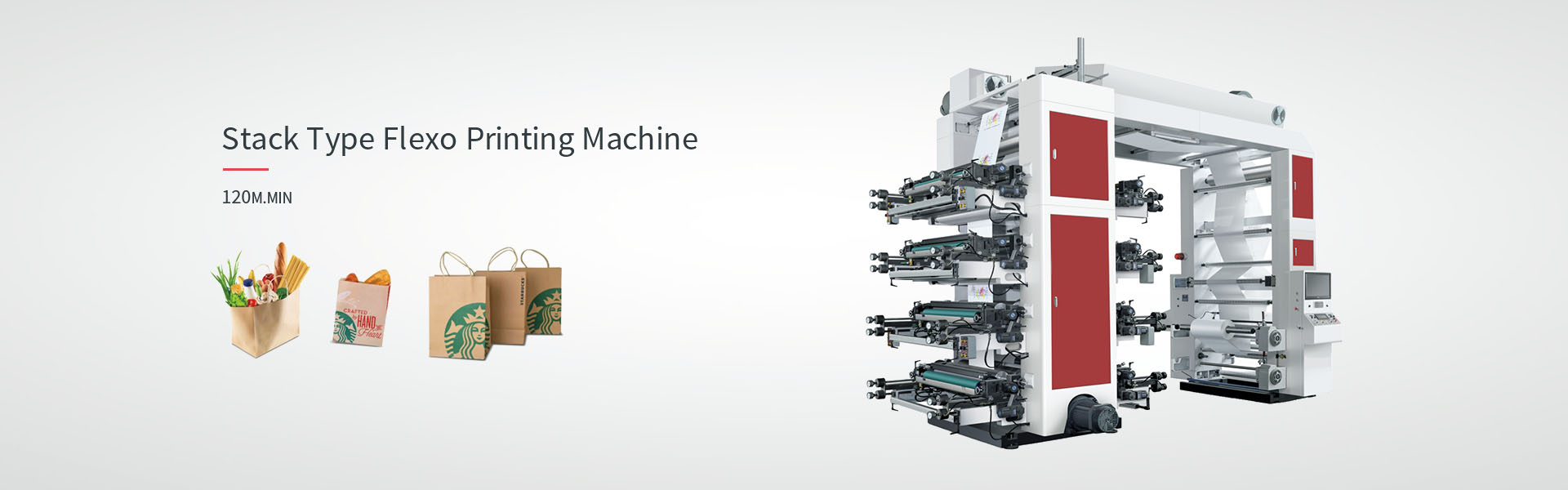

Paper packaging, paper bag, paper box, milk carton, flexible packaging, breathable film etc

Coated paper, paperboard, non-woven fabric, light-weight coated paper, kraft paper and paper-plastic composite material, etc

The F2 series medium web flexo printing features delivers the fastest set-ups and changeovers and shorter web path and fastest make-ready times in the industry. Additional advantages over traditional presses include short web paths, without adjusting pressure after changeover and minimal ink usage requirements resulting in waste savings up to 50% and fast changeover times for increased productivity. The max speed can reach 240m/min.

1. Stable printing:

Specially designed bearer-type cam supports and fastens the plate cylinder with a locking hook, which effectively overcomes the vibration caused by plate gap and achieve high-precision and stable printing;.

2. Fast change of cylinders:

Specially designed bearer-type structure enables fast change of plate cylinders without adjusting printing pressure, which greatly improves production efficiency.

3. Short paper path design:

Design of short paper path greatly reduces production cost.

4. Pre-register function:

Servo-driving pre-registering function improves production efficiency and also reduces waste of printing materials in register debugging.

5. Accurate registering:

Accurate registering produces qualified prints in the acceleration and deceleration process.

6. Non-stop web unwinding and rewinding (optional function):

Printing materials can be changed during high-speed printing without power off, which improves production efficiency and reduces product costs

| Max web width | 720mm | 920mm | 1020mm | 1220mm | 1220mm |

| Max printing width | 700mm | 900mm | 1000mm | 1200mm | 1200mm |

| Max die cutting width | 700mm | 900mm | / | / | / |

| Printing Repeated length | 300-900mm | 300-900mm | 300-900mm | 300-900mm | 300-900mm |

| Die cutting repeated length | 500-800mm | 565-800mm | / | / | / |

| Max unwinding diameter | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm |

| Max rewinding diameter | 1524mm | 1524mm | 1524mm | 1524mm | 1524mm |

| Driving mode | Single servo motor driven/dual servo motor driven | Dual servo motor | |||

| Gearing mode |

GP1/8 |

||||

| Impression cylinder diameter |

128T |

160T |

|||

| Anilox roller diameter |

128T |

128T |

|||

| Max mechanical speed |

240m/min |

||||

| Drying mode |

Hot air drying/IR drying/UV vdrying |

||||

| Applicable ink |

Eco friendly water based ink/solvent based ink/UV ink |

||||

| Printing substrates |

Paper/film (PET/BOPP/BOPA) |

||||

| Thickness |

Paper:gsm range (max-min)=180 (single servo motor driven) Paper: gsm range (max-min)=280 (dual servo motor driven) |

||||